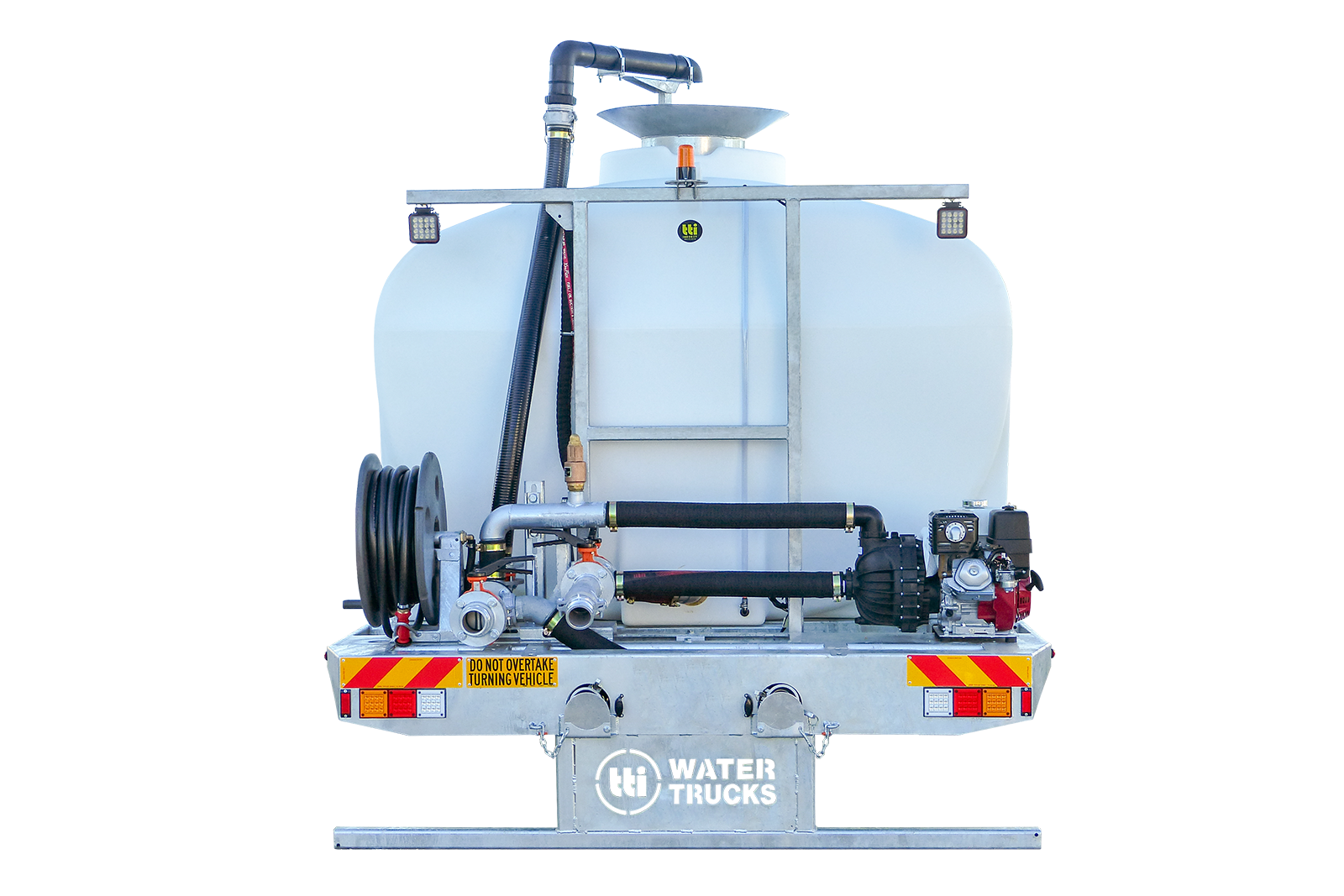

Turn your existing truck into a water DELIVERY UNIT

TTi offers remote supply modules, which is the perfect solution if you have the desire to do your own ‘fit-off’ of a complete water cart module.

Design, fabrication and testing of steel componentry is all completed in house, before being hot-dip galvanised ready for final assembly.

The module is then fully assembled and tested one of our state-of-the-art facilities, ready for sign off and mounting to the truck of your choice.

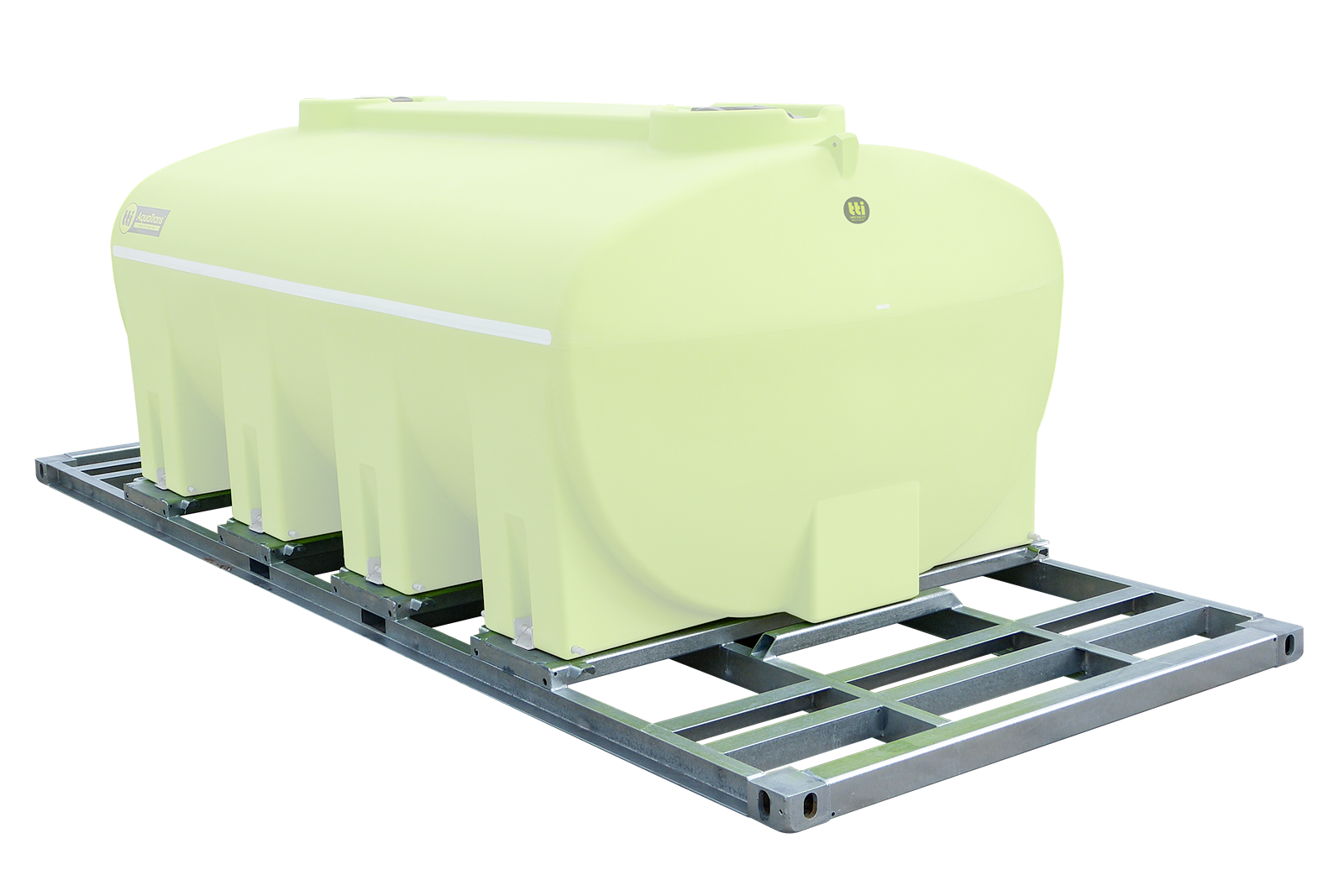

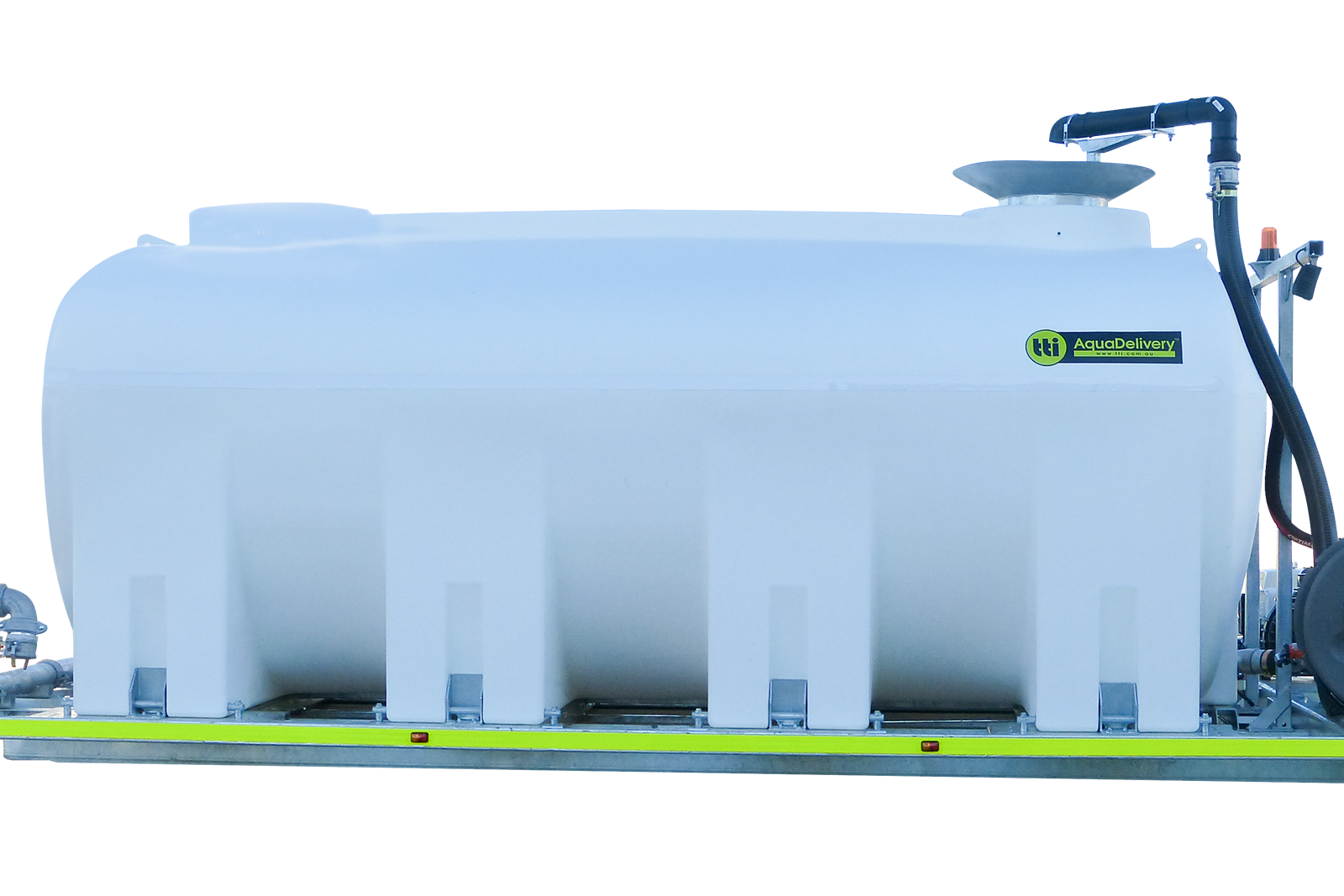

Heavy-Duty Poly Tank

Thick & tough poly tank complete with a 25 Year Warranty

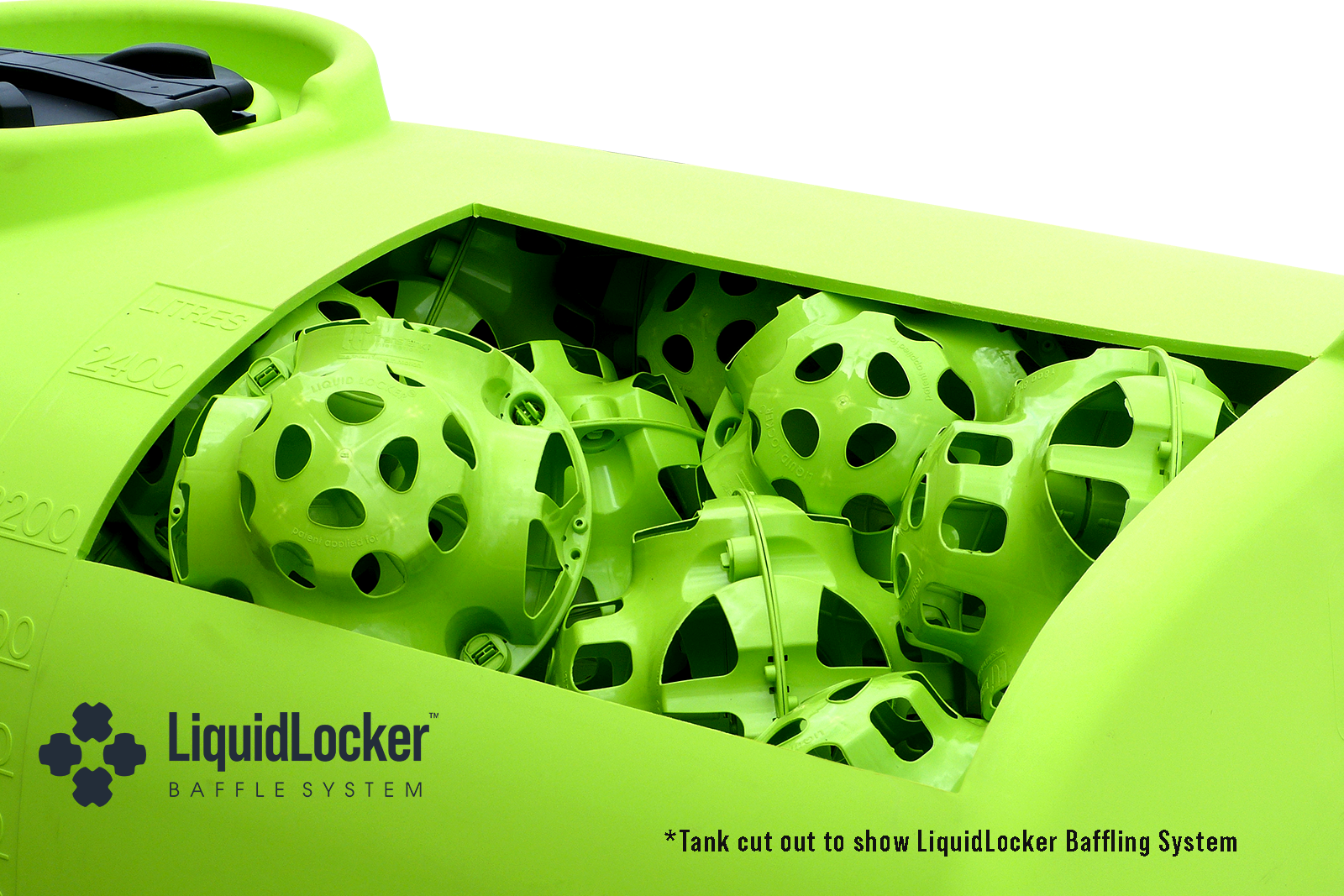

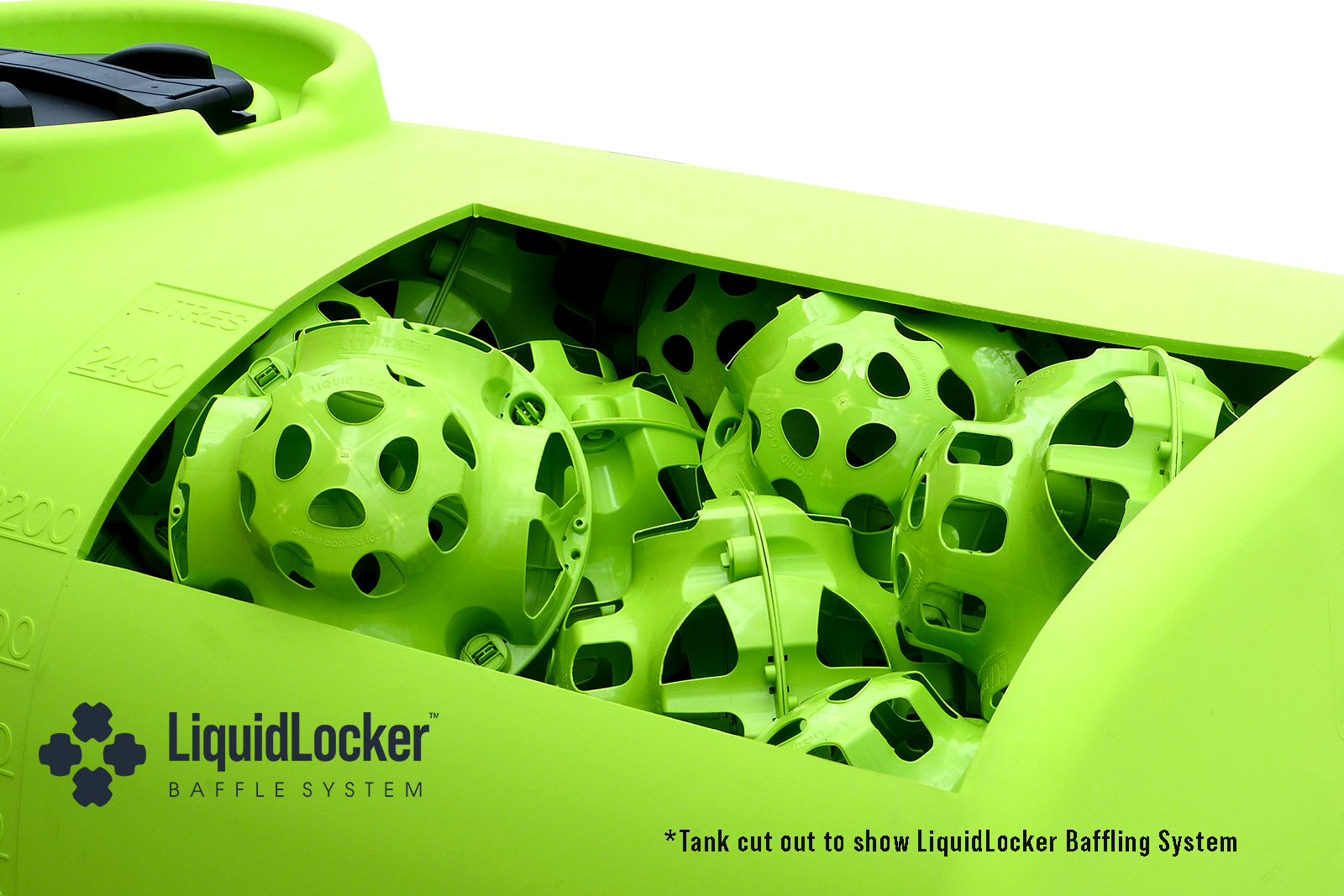

LiquidLocker™ Baffle System

LiquidLocker baffling system fitted to eliminate liquid surge

Hot Dip Galvanised Chassis Frame

Engineer approved chassis frame with mounting kit

Hydrant Filler Lid System

Fitted with a 3″ hydrant fill lid plumbed down to a Spring non-return valve

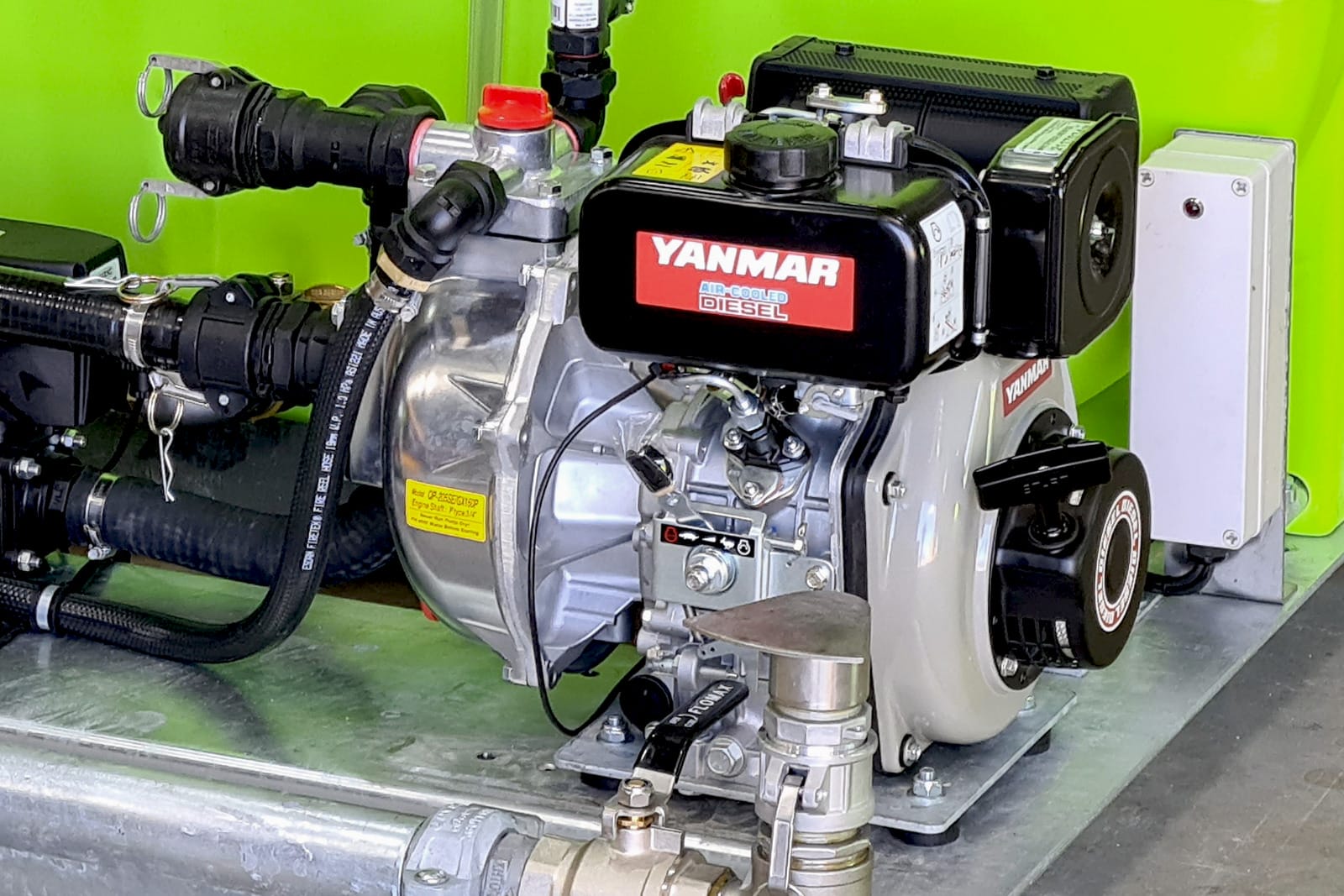

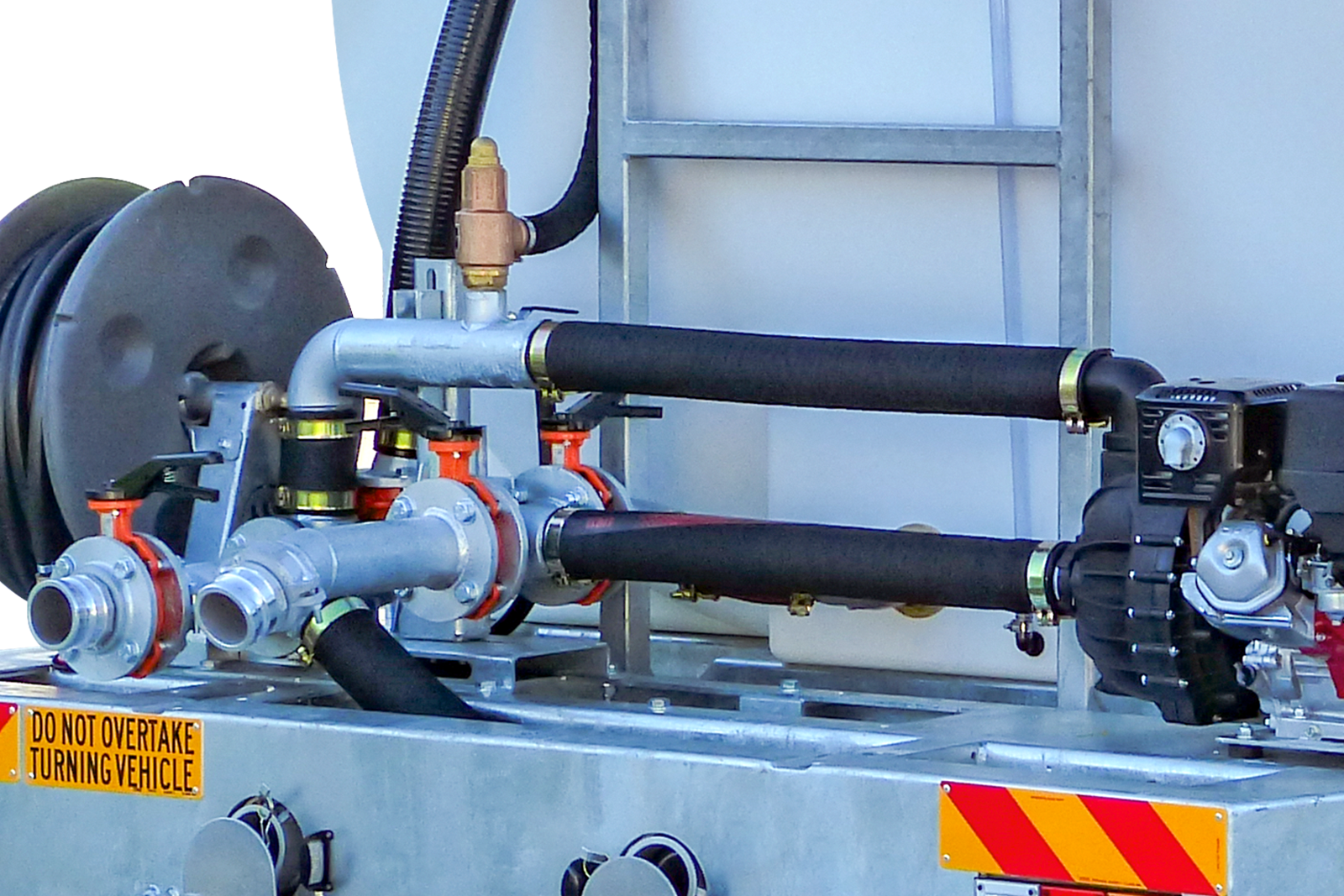

Hydraulic, Diesel or Petrol Option

Yanmar 10hp Engine, Honda Petrol or Hydraulic drive options

Suction Hose Storage

Hose Storage between chassis rails - 2x 5m lengths, 3"

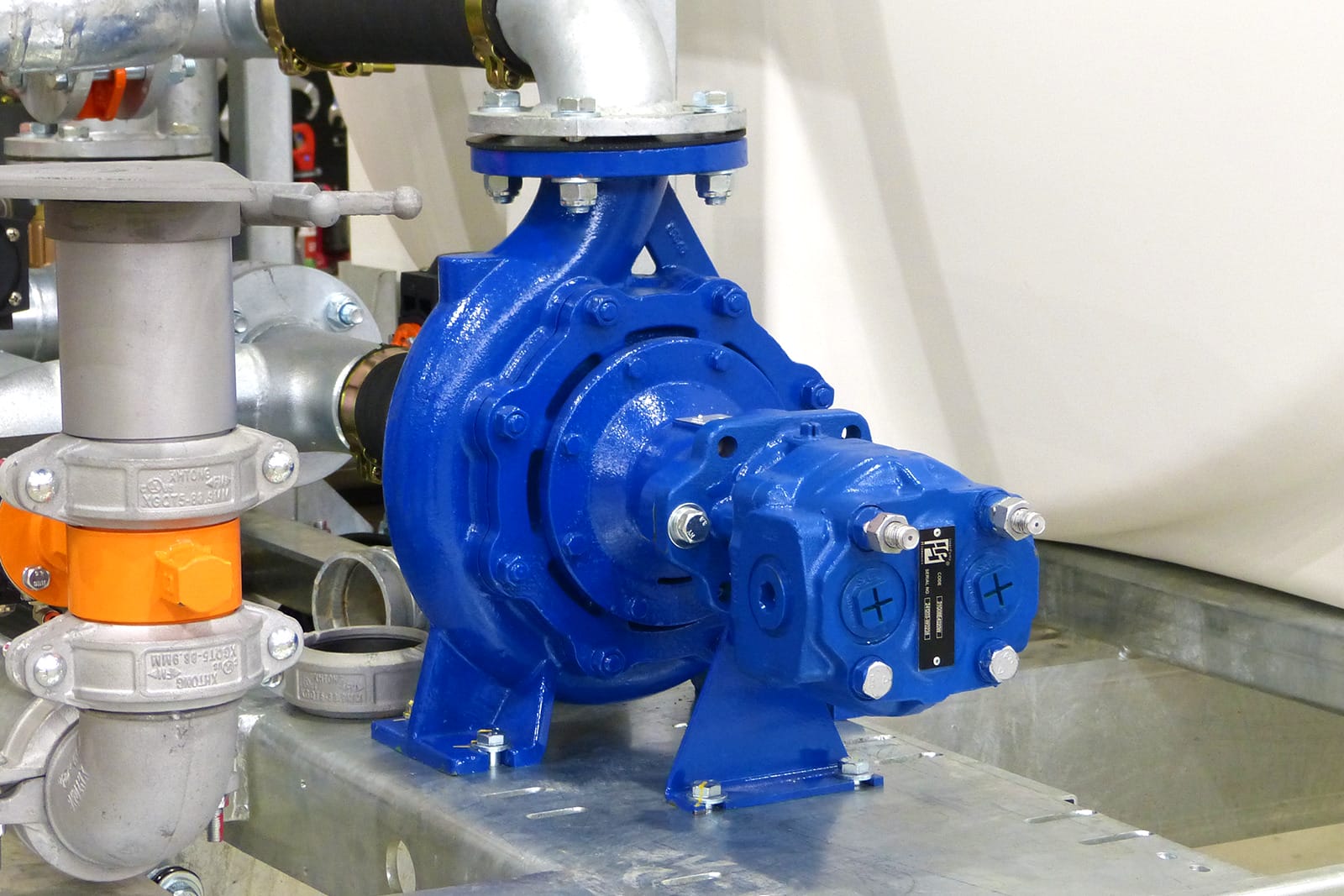

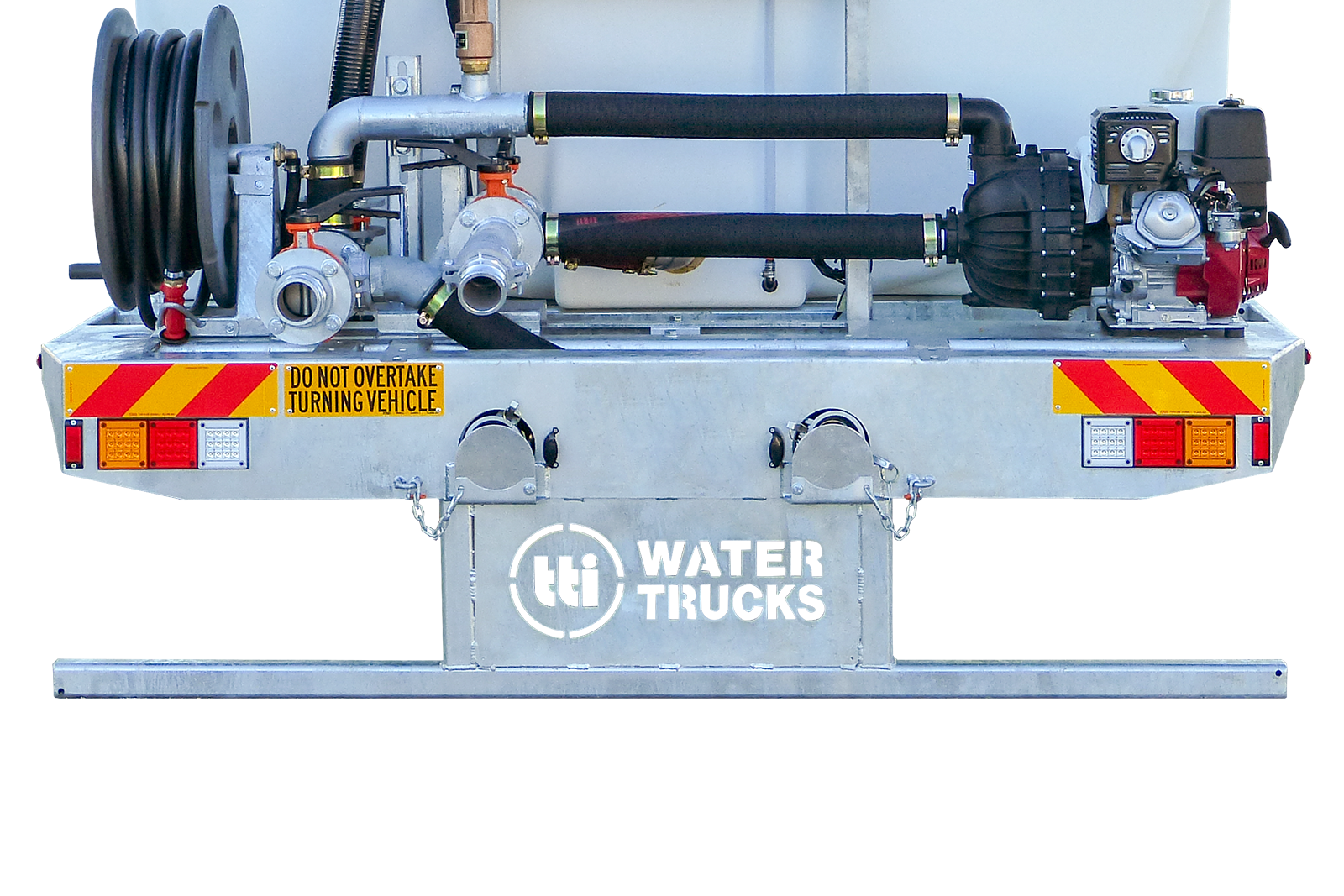

3" Steel Manifold Pipework

Hot dip galvanised. 3" dedicated suction and discharge ports with camlock fittings

Rear Bumper Taillight

Rear bumper incorporating a taillight board with LED tail and number plate lights

Browse through the main features of TTi water trucks.

- Heavy-Duty Poly Tank - Thick & tough poly tank with a 25 Year Warranty

- LiquidLocker™ Baffle System - LiquidLocker baffling system fitted to eliminate liquid surge

- Hot Dip Galvanised Chassis Frame - Engineer Approved Chassis Frame with mounting kit

- Honda GX200 (Electric Start) Motor QP303 1000L/min Transfer Pump with Petrol or options

- Rear bumper incorporating a taillight board with LED tail and number plate lights

- 3" Steel Manifold Pipework, hot dip galvanised. 3" dedicated suction and discharge ports with camlock fittings

- Funnel Lid for overhead standpipe filling

- Hydrant Fill System with regulation air-gap, 3" one-way valve connection point

- Suction hose storage between chassis rails - 2x 5m lengths, 3"